The SAU Engineering program operates its own 3D printing lab facility. At the Southern Arkansas University prototyping lab you can make prototypes of your products. Our experts can convert your ideas into the CAD models and then turn them into prototypes. We can also use your CAD model in any format and make the prototype for you. We offer expertise in the following engineering analyses: Solid Modeling, Finite Element Analysis for product design, Computational Fluid Dynamics simulation for your fluid flow system, and Thermal Design. The prototyping lab functions as a separate lab and currently has several different types of 3D printers. The lab is used by engineering students from freshman to senior level and is a valuable resource for senior design projects.

The SAU Engineering program operates its own 3D printing lab facility. At the Southern Arkansas University prototyping lab you can make prototypes of your products. Our experts can convert your ideas into the CAD models and then turn them into prototypes. We can also use your CAD model in any format and make the prototype for you. We offer expertise in the following engineering analyses: Solid Modeling, Finite Element Analysis for product design, Computational Fluid Dynamics simulation for your fluid flow system, and Thermal Design. The prototyping lab functions as a separate lab and currently has several different types of 3D printers. The lab is used by engineering students from freshman to senior level and is a valuable resource for senior design projects.

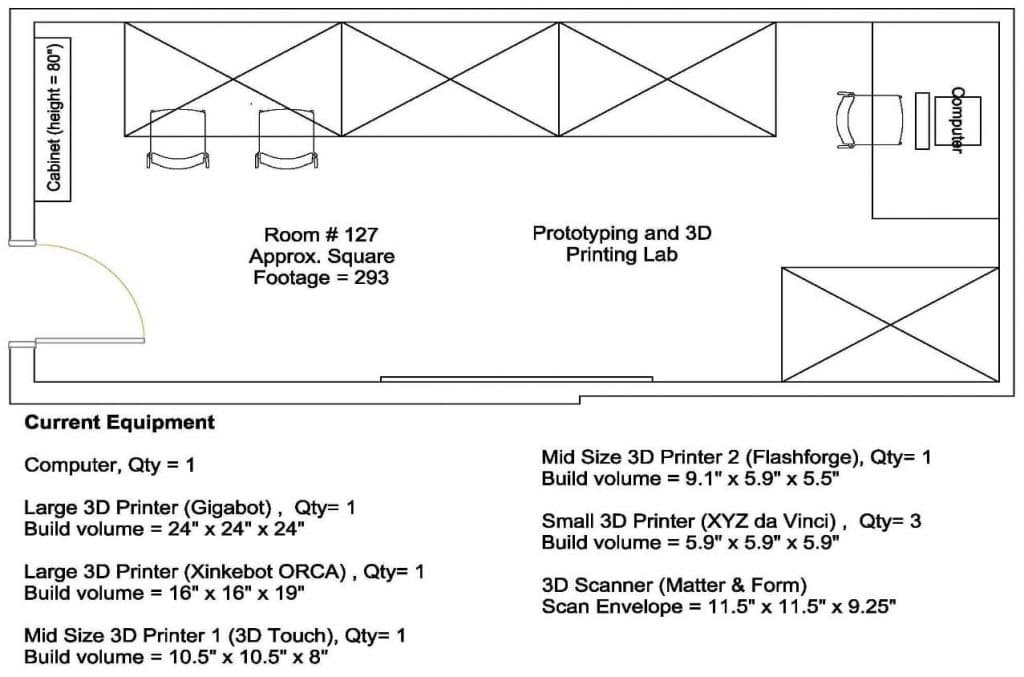

3D Touch

3D Touch

This is the first 3D printer that we acquired in 2012. Since then we have used it extensively. The printer has a build volume of approximately 10.6″ x 8.1″ x 8.3″. The printer is capable of printing both PLA and ABS filaments. It prints directly from a USB drive. The z-axis precision is 0.125 mm. The associated slicing software to make the z-code is Axon. The filament size is 3 mm, which is common in many 3D printers.

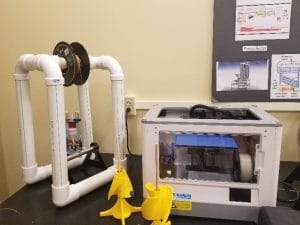

re:3D Gigabot

re:3D Gigabot

This is the second 3D printer that we added to our lab in spring 2015 using a NASA grant, with additional funds from the SAU Foundation. It is our largest 3D printer, and has a build volume of approximately 24″ x 24″ x 24″. It is capable of using both PLA and ABS filaments of a diameter of 3 mm. This printer has also been used extensively since it was purchased. The associated slicing software is Simplify3D, which is capable of making z-codes at different infill patterns and different infill percentages. The printer has a heated bed covered with a special material called buildTak that helps the print to stick to the surface.

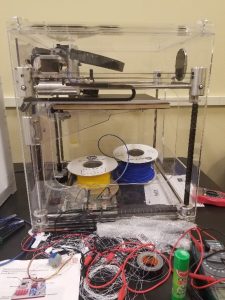

FlashForge Dreamer

FlashForge Dreamer

This printer was purchased at the end of spring 2015. The build volume of this printer is 9.1” x 5.9” x 5.5” and it can print from both PLA and ABS filaments with a diameter of 1.75 mm. This printer is ideal for printing small objects with relatively high precision. The printer has a heated bed. It came with its own software called Flashprint.

XYZ da Vinci

XYZ da Vinci

Three more 3D printers of the same kind were purchased right before Summer 2016 to conduct summer camp activities. The XYZ da Vinci 3D printer is ideal for doing class projects for the students in the Introduction to Engineering Lab class. The build volume is 5.9” x 5.9” x 5.9” and it uses PLA filament.

Ultimaker2 Extended+

Ultimaker2 Extended+

Engineered to perform, the Ultimaker2+ is reliable, efficient, and user-friendly. It supports of a wide range of materials, it’s suitable for a huge variety of applications, from prototypes to customized tools. It’s a great all-around 3D printer that delivers consistent results.

Easily switch between the included 0.25, 0.4, 0.6, and 0.8mm nozzles for greater detail or faster print speed. Premium materials used in construction. Heated bed smooths prints and allows for ABS printing.

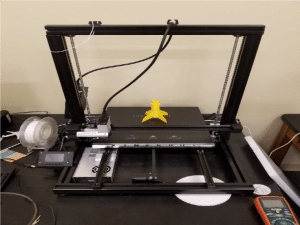

Xinkebot Orca 2 Cygnus

Xinkebot Orca 2 Cygnus

The Orca 2 Cygnus is a large 3D printer from Xinkebot. It has a big build size of 400 x 400 x500 mm and an aluminum heat bed with auto leveling. It also has a direct drive extruder that is capable of printing many different kinds of filament, including flexible filament like TPU and TPE. Unlike many other similar 3D printers on the market, it is built with higher quality materials which ensure its reliability in a long print job. With the integrated operating system, you can control everything easily on the LCD touch screen.

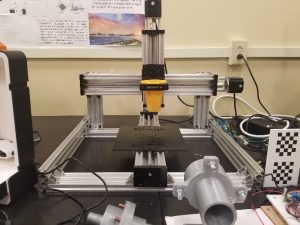

Cartesian Pick-and-Place Robot & Mini CNC Machine

Cartesian Pick-and-Place Robot & Mini CNC Machine

This is a small numerical controlled (CNC) machine that was built by a group of students as part of their honors class. The students used a hobby CNC kit to construct the machine; major components include linear rails made of aluminum, NEMA 17 stepper motors for all three axes, a dc power source (12V-24V), and a motor controller to control and run the stepper motors for the corresponding axes. The maximum linear movement for both X and Y axis are 500 mm. As part of the initial project, a magnetic gripper was attached to the machine. However, an interchangeable spindle can be incorporated to transform it into a small CNC mill as well.